Delta Ac Servo Drive User Manual

We provide all Delta AC Drives, VFD’s, Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion Control Network, Delta Programmable Logic Controller, Delta Human Machine Interfaces, Delta Text Panels, Delta Temperature Controllers, Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta Brushless DC Motors as well as Delta Brushless DC Drives.

- Delta Ac Servo Drive User Manual Instructions

- Mitsubishi Servo Drive Manual

- Ac Servo Drive Theory

- Delta Ac Servo Drive User Manual Pdf

Delta Ac Servo Drive User Manual Instructions

Delta AC Servo Motor and Drive ASDA-B2 Series

This manual will be helpful in the installation, wiring, inspection, and operation of Delta AC servo drive and motor. Before using the product, please read this user manual to ensure correct use. You should thoroughly understand all safety precautions. View and Download Delta Electronics AC Servo Drive ASDA-B quick start manual online. Delta Electronics Network Device Quick Start Guide. AC Servo Drive. Delta Electronics Device DOP-A/AE/AS User Manual (137 pages) the right to change the information in this manual without prior notice, delta DOP Series HMI. Offer for Delta Plc, Hmi, Ac drive, Spindle drive, Encoder, servo drive and servo. Plc, Delta Delta PLC programming manual PDF.pdf 15.89MB. The user must operate the product. The Next Revolution in Servo Performance. Sigma-7 products set a new industry standard in servo capability, with features that advance Yaskawa’s 25-year reputation for redefining the possibilities in motion automation.

Delta sales representative. Place this user manual in a safe location for future reference. Using This Manual Contents of this manual This manual is a user guide that provides the information on how to install, operate and maintain ASDA-B series AC servo drives and ECMA series AC servo motors. The contents of this manual. Jan 05, 2015 AC Servo Drives- Delta ASDB B Series 1. SERVO DRIVE MECHANISM POSITION VELOCITY TORQUE LOAD Conveyor Pump Grinder Wheel Machine Fans/ Compressor POWERSOURCE CONTA CTOR SERVO DRIVER SERVO MOTOR PLC (TRANSISTOR TYPE) CONTROL SIGNAL (IN PULSES) FEEDBACKSIGNAL 1/3220VAC 2.

INTRODUCTION

The power rating of the ASDA-B2 series is offered from 0.1kW to 3kW. The superior properties of this series emphasize on “built-in generic functions for general-purpose applications” and “avoiding variable costs from mechatronics integration.” When Delta’s ASDA-B2 series is in use, the users can conveniently complete assembly, wiring and operation setups. In addition, in switching from other brands to Delta’s ASDA-B2 series, outstanding quality and features, and complete product lineup make the replacement easy and quick to achieve. Using Delta ASDA-B2 series, not only the wiring and operation becomes much easier, and the requirements of general-purpose machine tools for the market could be satisfied as well. Moreover, the customized solutions are available on request for different industries so that make ASDA-B2 series be widely popular and always in demand by the customers in the field of industrial automation.

FEATURES

High-resolution encoder with 17-bit (160,000 p/rev) is equipped as a standard feature which satisfies the application needs of high precision positioning control and stable rotation at low speed.

Satisfy High Precision Positioning Requirements

Support pulse input (up to 4Mbps) and analog voltage two kinds of command.

Built-in position, speed and torque three control modes (speed and torque mode could be controlled via internal parameters or analog voltage command).

There auto notch filters are provided to suppress the mechanical resonance automatically and make the system operate more smoothly.

Offer Easy-To-Install Solution for Simple Start-Up

Motor sizing software is offered for the customers to conduct the estimation of the equipment conveniently.

ASDA-Soft configuration software (tuning software) is provided for the customers to meet the performance requirements quickly.

Easy-to-use digital keypad is ideal for setting parameters and monitoring the servo drive and motor directly.

Servo motor provides brake, oil seal etc. optional configurations for the requirements of different applications.

Reduce Maintenance and Wiring Cost for Versatile Operation

Existing power cables and encoder cables for ASDA series could be used still. When upgrading, there is no need to purchase new accessories.

The control circuit and main power circuit is separated, safety is increased and maintenance is much easier.

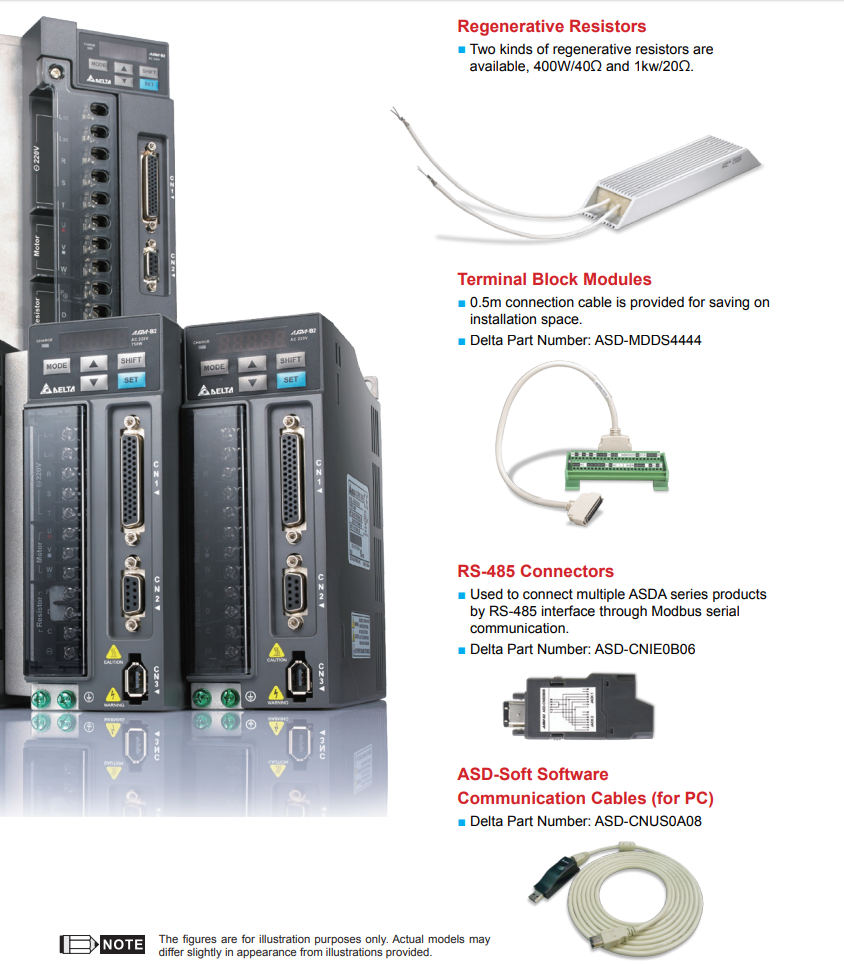

400W and above servo drive is built-in with regenerative resistor, significantly save the wiring and cost.

Two analog input terminals (CN5) are provided, easily monitor and the status of the servo motor.

Downloads:

Purchase your Delta ASDA-B2 AC Servo Motors today!

We provide all Delta AC Drives, VFD’s, Delta AC Servo Motors, Delta Rotary Optical Encoders, Delta Motion Control Network, Delta Programmable Logic Controller, Delta Human Machine Interfaces, Delta Text Panels, Delta Temperature Controllers, Delta Industrial Fieldbus Solutions, Delta Pressure Sensor, Delta Brushless DC Motors as well as Delta Brushless DC Drives.

Mitsubishi Servo Drive Manual

Delta AC Servo Motor and Drive ASDA-A Series

Ac Servo Drive Theory

FEATURES

The A series is an omnibearing integrated servo system with advanced functions. Not only pulse commands and analog voltage signal control, the A series also provides internal point-to-point position control mode (8 internal programmable registers) and offers various internal control functions such as: indexing, feed step control function, internal auto-running control mode, and move to Home function, etc. for a vast range of applications. In addition, the A series implements Modbus communication protocol as a standard, to perfectly meet the requirements of motion control applications for multiple points.

The A series servo system provides a better solution for industrial processing machinery and motion control equipment.

SPECIFICATIONS

A wide power range: from 100W to 1.5kW, 1-phase or 3-phase; from 2kW to 3kW, 3-phase

Input power supply: AC 200V ~ 230V

Built-in Position / Speed / Torque control modes

8 internal programmable registers (point-to-point position control)

Internal control function: Indexing, Feed step control function (for cutting applications)

Internal control function: Internal auto-running control mode

Internal control function: Move to Home (Homing) function

Internal control function: Position teaching function (JOG mode)

Programming is done via the built-in keypad or using Delta’s free Windows® based software where the user can store, teach, and monitor the operation of the servo system.

Modbus communication protocol is supported as standard. Communication Interface: RS-232 / RS-485 / RS-422

APPLICATIONS

Cutting control of machining center, rotary indexing machine, sealing machine, shearing machine, feeding machine, carving machine, lathe, high-speed winding machine, testing / inspecting Machine, cutting machine, SMT machine, molding machine

SERVO DRIVE AND SERVO MOTOR COMBINATIONS

Delta Ac Servo Drive User Manual Pdf

Downloads: